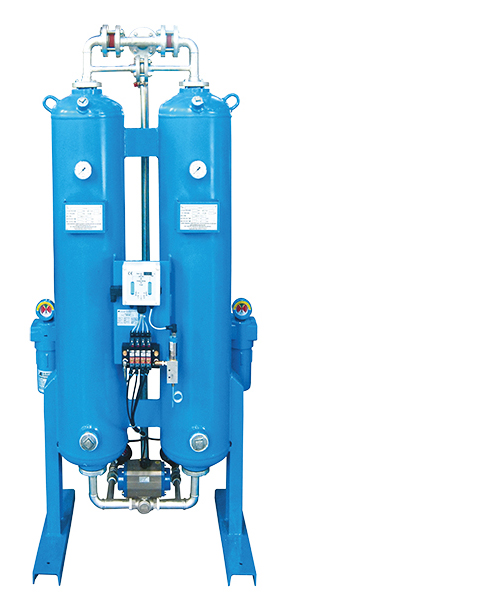

Adsorption Dryers

The Problem

Compressed air is a commonly used power source. Over the years it became a crucial part of a wide range in industrial processes. However, compressed air after compression is not clean and contains impurities like water, oil, dirt, wear particles and so on. This mixture creates a form of condensate which damages downstream equipment like air tools, pneumatic cylinders and other pneumatic equipments. It also causes high product rejects, high maintenance and costly air leaks in compressed air systems. The use of highly efficient compressed air filters and condensate drains will remove a lot of these impurities and can eliminate most of the problems downstream.

For many applications this is not enough. These applications need an even higher level of compressed air quality. AFE’s compressed air adsorption dryers desiccant dryers will provide this level of air quality at the point where the quality is needed without investing a large amount in centralized purification systems which are often not needed because only certain areas of the production process need that high quality air.

The Solution

The AFE’s Series of compact desiccant air dryers offers users the air quality at the point where it is needed. Utilizing a reliable technology, the compressed air adsorption dryers provide the security to run the process without interruption and to have safe and reliable operations of downstream machines and air tools.

This series comes with installed pre- and afterfilter, desiccant fill and a reliable PCB controller with indication lights to monitor the operation. The PCB controller is ready build in and only has to be connected to an electrical power source and compressed air inlet/outlet. Optionally available is a dryer run/stop dry contact as well as a load control system for energy savings.

C-HDDN Series

C-HDADN Series

HDD Series

VEHDD Series